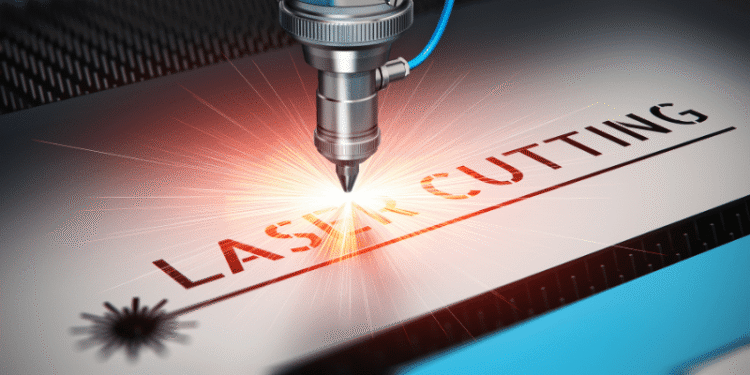

In the world of manufacturing and design, precision is key. Laser cutting stands out as one of the most reliable methods, offering unparalleled accuracy and versatility in various applications.

What is Laser Cutting?

Laser cutting is a technology that uses a laser to slice materials. It is typically used for industrial manufacturing applications, but it is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics.

How Does Laser Cutting Work?

The process involves the laser focusing on a small area of the material, either reducing it to vapour or blowing it away as molten material. The laser beam is directed at the desired material with the help of a computer, ensuring precise cuts according to the programmed designs. The precision and clean edges offered by laser cutting make it the technique of choice for many industries, from aerospace to electronics.

Advantages of Laser Cutting

One of the primary advantages of laser cutting is its precision. The ability to cut complex shapes and designs with high accuracy is crucial in sectors such as automobile manufacturing and intricate jewellery creation.

Moreover, laser cutting offers great flexibility. It can cut a range of materials, including metals, plastics, woods, and even some types of fabric. This versatility is beneficial for industries that require diverse production capabilities.

Efficiency and Cost-effectiveness

In addition to its versatility, laser cutting is known for its efficiency. It greatly reduces wastage of materials, as the precision allows for optimal utilisation of the material being cut. This aspect of production also makes it cost-effective, as it minimises the expenses related to material excess and disposal. Furthermore, the speed of laser cutting, compared with traditional cutting methods, ensures that production timelines are significantly shortened.

Enhanced Safety Features

Another crucial benefit of laser cutting is the enhanced safety it offers in the workplace. Traditional cutting methods can pose risks due to direct contact with blades or other cutting tools. In contrast, laser cutting is a non-contact process, minimising the risk of workplace injuries.

Applications of Laser Cutting

Laser cutting has broadened its scope of application across several industries. For instance, in the automotive industry, it is used to create components with high precision. In electronic manufacturing, laser cutting helps in making intricate circuits. The technology is also extensively used in the fashion industry for detailed fabric patterns.

In architecture, laser cutting is used to produce detailed models and prototypes, which help in visualising and planning building layouts. This enhances the creativity and innovation potential in this field.

Environmental Considerations

Laser cutting is also environmentally friendly, as it produces less waste compared to traditional cutting methods. The precision reduces excess material use, contributing to sustainable manufacturing efforts.

Future of Laser Cutting Technology

The future of laser cutting is promising, with continuous innovations enhancing its capabilities. Advances in laser technology are likely to introduce faster, more efficient methods of cutting, while expanding the range of materials that can be processed.

As industries seek more sustainable and efficient methods of production, laser cutting will play a central role in these efforts. Its ability to adapt to various materials and designs will keep it at the forefront of manufacturing technology.

Choosing the Right Laser Cutting Service

When choosing a laser cutting service, it is essential to consider factors such as the precision of the machinery, the range of materials that can be cut, and the provider’s reputation within the industry. Engaging with a reputable provider such as Laser Central Pty Ltd ensures that quality and reliability are part of your manufacturing process.