Laser welding is becoming very popular. It is fast, clean, and works well with many types of metal. If you are considering buying a laser welding machine, this guide will help you understand what to look for.

In this article, we’ll discuss the benefits of laser welding and the costs to consider. It’s written in simple language so everyone can easily understand. For more details, check out a trusted Laser Welding Machine Manufacturer.

What Is a Laser Welding Machine?

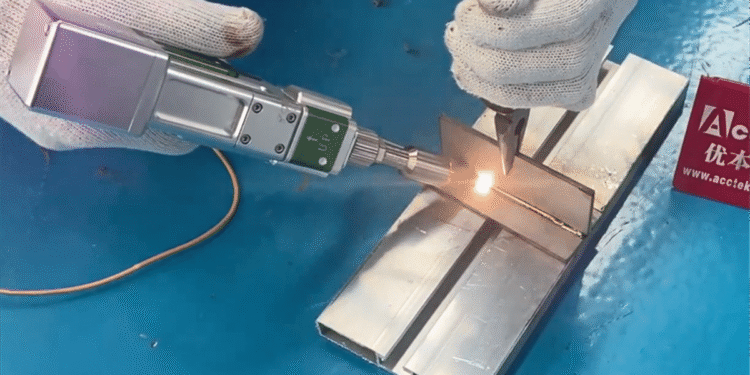

A laser welding machine uses an intense laser beam to join metal parts. The laser melts the edges of the metal, and they stick together when cooled. This process is quick and clean.

Laser welding works well for:

Stainless steel

Aluminum

Copper

Titanium

Carbon steel

It is used in many industries, such as automotive, electronics, medical devices, and aerospace.

Benefits of Laser Welding Machines

Laser welding has many advantages over traditional welding. Let’s look at the main benefits:

1. High Precision

Laser welding is very accurate. It can weld tiny parts without damaging nearby areas. This is great for small items like phone parts or medical tools.

2. Fast Welding

Laser welding is much faster than old methods. You can finish more work in less time. This helps factories save time and make more products.

3. Strong Joints

The welds made by laser are robust. They can handle high pressure and heat. This is perfect for parts that need to last a long time.

4. Clean and Neat

Laser welding creates clean lines and does not leave much mess. No need for extra cleaning or grinding. This reduces work time.

5. Low Heat Damage

The laser beam is focused. It does not heat the whole part. This means less warping or bending of materials.

6. Works with Many Metals

Laser welding works well with many types of metals and alloys. You can also join different kinds of metals together.

Types of Laser Welding Machines

There are different types of laser welding machines. You need to choose the one that fits your needs.

1. Fibre Laser Welding Machine

Good for metal parts

High speed and low power use

Long service life

2. CO2 Laser Welding Machine

Best for non-metal materials (like plastic or wood)

Used in packaging and cutting, too

3. Nd: YAG Laser Welding Machine

Used for fine and delicate welding

More complex and costly

If you mostly weld metal, a fibre laser machine is usually the best choice.

How to Choose the Right Machine

Here are the main things to think about when picking a laser welding machine:

1. Material Type

What kind of material are you welding? If you work with metal, a fibre laser is best. For plastic or wood, go with a CO2 laser.

2. Thickness of Material

Some machines work better with thin metals. Others can handle thick parts. Check the machine specs before buying.

3. Welding Speed

If you need to weld many parts fast, choose a machine with high speed. This saves time and increases output.

4. Power Level

Higher power means deeper welds. Choose the right power based on your job. Most small jobs need 1000w–2000w. Bigger jobs may need 3000w or more.

5. Ease of Use

Pick a machine that is easy to use. Many new machines have touchscreen controls and smart settings.

6. Cooling System

Laser machines get hot. A sound cooling system helps keep the machine safe and running well.

Cost Considerations

Laser welding machines may not be inexpensive, but they offer great value over time. Let’s break down the costs with a closer look at the Laser Welder Cost.

1. Initial Cost

Small fibre laser machines: $6,000 – $15,000

Medium machines: $15,000 – $30,000

Large industrial machines: $30,000 – $100,000+

2. Operating Costs

Good news—laser welding uses less power than older machines. Also, you don’t need filler materials or gas in most cases.

3. Maintenance Costs

Laser machines need less maintenance than traditional welders. However, make sure to keep them clean and check cooling systems often.

4. Training Costs

Operators need training to use the machine safely. Many sellers offer free training with the machine.

Is It Worth the Investment?

Yes, in most cases.

Even though laser machines cost more upfront, they save money in the long run. You get:

Faster work

Better quality

Less waste

Lower labor costs

For factories and workshops, laser welding is a wise choice. It helps grow your business and stay ahead of the competition.

Safety Tips

Laser machines are powerful. Always follow these safety steps:

Wear laser safety glasses.

Use proper ventilation

Keep the area clean

Don’t look directly at the laser.

Follow the user manual carefully.

Conclusion

Choosing the right laser welding machine is very important for your business. It helps you work faster, safer, and better.

Before buying, think about:

What materials will you weld?

How thick the material is

Your welding speed needs

Your budget

Fibre laser machines are the most common and useful for metal welding. They offer many benefits, like clean welds, strong joints, and low maintenance.

If you invest wisely, a good laser welding machine can save time and money and improve your work quality.