Deep hole drilling in exotic alloys like titanium, Inconel, and Hastelloy is highly challenging due to their strength, corrosion resistance, and temperature stability. These materials, widely used in aerospace, medical, and energy industries, demand precision and expertise. This guide outlines best practices to overcome these challenges, improve results, and minimize costly errors.

Understanding the Challenges of Drilling Exotic Alloys

Exotic alloys present a unique set of challenges that standard drilling approaches cannot adequately address. These materials often exhibit work hardening characteristics, meaning they become increasingly difficult to machine as cutting tools generate heat and pressure. Additionally, their low thermal conductivity can cause heat buildup at the cutting zone, leading to tool wear and potential workpiece damage.

The combination of high strength and abrasive properties common in exotic alloys accelerates tool wear, while their tendency to form built-up edge on cutting tools can compromise surface finish and dimensional accuracy. These factors make traditional drilling parameters and techniques inadequate for achieving the precision required in critical applications.

Chip evacuation becomes particularly problematic when drilling deep holes in these materials. Poor chip removal can cause re-cutting, increased heat generation, and eventual tool failure. The narrow margins for error when working with expensive exotic alloys make understanding these challenges crucial for successful operations.

Material Selection and Preparation Best Practices

Successful deep hole drilling begins with proper material selection and preparation. Understanding the specific grade and condition of your exotic alloy is essential, as different heat treatments and compositions can dramatically affect machinability. Always verify material certificates and conduct hardness testing to ensure consistency with your drilling parameters.

Pre-machining preparation should include stress relieving when possible, as residual stresses can cause dimensional instability during drilling. Surface preparation is equally important—removing scale, oxidation, or other surface contaminants prevents premature tool wear and ensures consistent cutting conditions.

Consider the grain structure and orientation of your material. Some exotic alloys exhibit directional properties that can influence drilling performance. Whenever possible, orient deep holes to take advantage of favorable grain direction, though this is not always feasible given design constraints.

Optimizing Drilling Techniques and Parameters

Parameter optimization requires a systematic approach when working with exotic alloys. Start with conservative cutting speeds and feeds, then gradually optimize based on tool performance and hole quality. Generally, exotic alloys require lower surface speeds than conventional materials, but this must be balanced against the need for sufficient chip load to prevent work hardening.

Constant surface speed control becomes critical for maintaining consistent cutting conditions throughout the drilling process. As drill diameter varies or when using specialized geometries, maintaining optimal surface speed helps preserve tool life and hole quality.

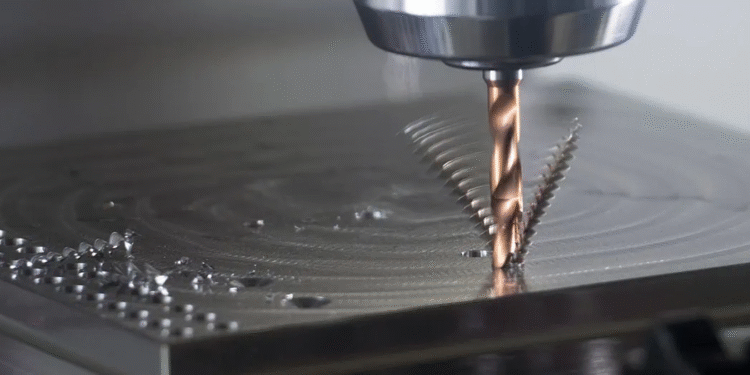

Coolant delivery deserves special attention in deep hole drilling operations. High-pressure coolant systems not only provide essential cooling but also aid in chip evacuation. The coolant should reach the cutting zone effectively, which may require specialized delivery systems such as through-tool coolant or high-pressure external systems.

Peck drilling cycles can be beneficial for chip breaking and heat dissipation, but the specific cycle parameters must be tailored to the material being drilled. Some exotic alloys respond better to shorter, more frequent pecks, while others benefit from longer drilling cycles with strategic withdrawal points.

Advanced Tooling and Equipment Considerations

Tool selection for deep hole drilling in exotic alloys requires careful consideration of geometry, coating, and substrate materials. Carbide tools with specialized coatings such as TiAlN or diamond-like carbon can provide superior performance in these demanding applications. The tool geometry should be optimized for the specific alloy being drilled, with appropriate point angles, helix angles, and chip evacuation features.

Specialized deep hole drilling systems, such as BTA (Boring and Trepanning Association) or gun drilling equipment, offer significant advantages for challenging applications. These systems provide superior coolant delivery and chip evacuation compared to conventional drilling methods.

Equipment rigidity cannot be overstated in its importance. Any vibration or deflection during the drilling process can lead to poor hole quality, accelerated tool wear, and potential workpiece scrapping. Consider using a bottom hole assembly like those available in Wyoming for enhanced stability in critical applications.

Modern monitoring systems can provide real-time feedback on drilling conditions, allowing operators to detect problems before they result in tool failure or workpiece damage. Vibration monitoring, power consumption tracking, and acoustic emission sensors can all contribute to process optimization.

Workholding and Fixturing Solutions

Proper workholding is fundamental to successful deep hole drilling operations. The workpiece must be securely clamped to prevent movement or vibration, but clamping forces should be distributed to avoid distortion. Exotic alloys can be particularly sensitive to clamping stresses, which may cause dimensional changes or cracking.

Consider using specialized fixtures that provide support near the drilling area while allowing for thermal expansion. Some operations may benefit from fixtures incorporating scratch-resistant plexiglass viewing windows for process monitoring while maintaining operator safety.

Backup support becomes crucial when drilling through materials, as breakthrough forces can cause significant deflection or damage. Plan your fixturing strategy to account for the complete drilling cycle, including tool entry, steady-state drilling, and breakthrough phases.

Quality Control and Process Monitoring

Implementing robust quality control measures ensures consistent results when drilling exotic alloys. Dimensional inspection should occur at multiple stages of the process, not just upon completion. In-process measurements can detect trends before they result in out-of-specification parts.

Surface finish monitoring provides valuable feedback on cutting conditions and tool condition. Exotic alloys often require specific surface finish requirements for their intended applications, making this measurement critical for quality assurance.

Hole straightness and cylindricity become particularly challenging in deep hole applications. Consider using specialized measurement equipment designed for deep hole inspection, and establish clear acceptance criteria based on application requirements.

Conclusion

Successfully drilling exotic alloys requires specialized strategies, proper equipment, and continuous process optimization. Standardizing procedures and learning from past projects can improve quality, reduce waste, and enhance productivity.