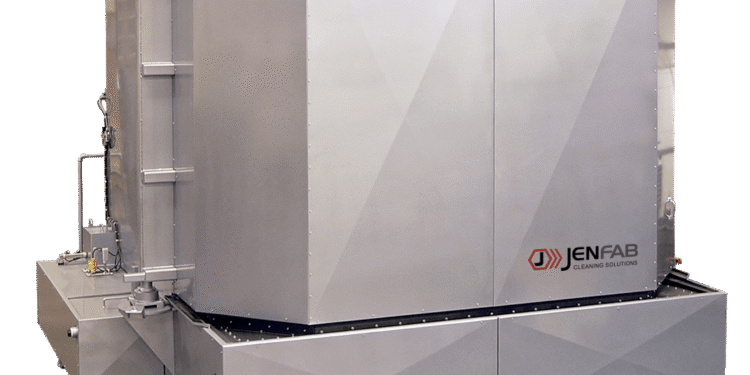

Image source: Jenfab

If you’re in manufacturing or maintenance, choosing the right parts washer can significantly impact your operation’s efficiency and bottom line. But with so many options available, how do you know which factors should be considered when selecting a parts washer?

When selecting a parts washer, the key factors to consider are part size and geometry, cleaning requirements, throughput needs, available space, environmental regulations, and budget constraints.

While these factors provide a basic framework, the reality is that each industry and application has unique requirements that can dramatically influence which parts washer is truly optimal. Understanding the nuances of how each factor applies to your specific situation will help you make a more informed decision and avoid costly mistakes.

How Do Part Size And Geometry Affect Parts Washer Selection?

The physical characteristics of your parts are crucial in determining the most suitable washer type. Large, bulky items may require a cabinet-style washer with a reinforced platform, while small, intricate parts might be better suited for an ultrasonic cleaner that can reach tight spaces. Additionally, parts with complex geometries or internal cavities need washers with spray patterns or agitation methods that ensure thorough cleaning of all surfaces.

Parts with varying shapes within your production line might require a more versatile washing solution. For instance, a combination washer that offers multiple cleaning methods could be more cost-effective than maintaining separate machines for different part types.

What Role Do Environmental Regulations Play In Parts Washer Selection?

Environmental compliance is becoming increasingly stringent across industries. Modern parts washers must meet specific requirements for waste disposal, VOC emissions, and water usage. Aqueous cleaners are gaining popularity over solvent-based systems due to their lower environmental impact and reduced regulatory burden.

Some regions have specific requirements about wastewater disposal and chemical usage. It’s essential to verify that your chosen parts washer complies with local, state, and federal regulations to avoid potential fines and operational disruptions.

How Does Production Volume Impact The Choice Of Parts Washer?

Your facility’s throughput requirements directly influence the type and size of parts washers needed. High-volume operations typically benefit from automated conveyor-style washers that can handle continuous processing, while batch-processing systems might better serve smaller operations.

Consider not just current production needs but also potential future growth. A parts washer that’s operating at maximum capacity from day one leaves no room for increased production demands. Choosing a system with 15-20% more capacity than current needs is often wise to accommodate future growth without requiring additional capital investment.

What Are The Cost Considerations Beyond The Initial Purchase Price?

While the upfront cost of a parts washer is significant, operating expenses often have a greater long-term impact. Energy consumption, water usage, cleaning agent costs, and maintenance requirements all contribute to the total cost of ownership. Some systems might have a higher purchase price but offer significant savings through reduced utility consumption or lower maintenance needs.

Labor costs should also factor into the equation. Automated systems might cost more initially but can reduce labor requirements and associated costs. Additionally, consider the cost of downtime for maintenance and the availability of replacement parts when calculating the true financial impact of your selection.

How Important Is The Choice Of Cleaning Chemistry In Parts Washer Selection?

The relationship between washing equipment and cleaning chemistry is often overlooked but critically important. Different materials and contaminants require specific cleaning agents, and not all parts washers are compatible with every cleaning solution. For example, some aggressive cleaning chemicals might damage specific washer components or seals.

Understanding the chemical compatibility of your parts is equally important. Some metals may react poorly with certain cleaning agents, leading to corrosion or surface damage. It’s essential to consider both the effectiveness of the cleaning chemistry and its compatibility with your parts and washing equipment. Many manufacturers recommend specific cleaning agents for their equipment, and deviating from these recommendations could void warranties or lead to suboptimal cleaning results.

Conclusion

Before making your final parts washer selection, create a detailed requirements document that lists your specific needs in each of the areas discussed above – from part specifications and production volume to environmental requirements and chemical compatibility. This comprehensive overview will help you make a more informed decision and serve as a valuable reference when consulting with equipment manufacturers or suppliers. Having this documentation ready will ensure you don’t overlook any critical factors and will help vendors provide more accurate recommendations for your specific application.